SELECTED

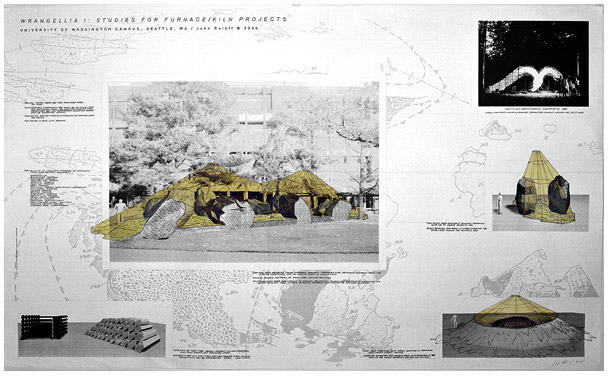

TEXT PANELS: WRANGELLIA I - left to right.

Yellow

tinted areas are fired areas/heat zones or flues. Kiln/furnaces components

are shown by yellow tint and structural lines; they are made of a steel

framework and high-temperature insulating blanket

or refractory cement. Insulating blanket kiln/furnaces are removed after

the firing. Firing is done by propane.

Two-row rock grouping from different geologic terranes with seafloor

sediment from the Juan de Fuca plate of the Pacific Coast of Washington.

Outside facing surfaces of base rocks are cut and polished. Kiln/furnace’s

form reminiscent of Cascade Mountains. Unpolished portions of rocks and

the space between them is fired, altering rocks

and fusing the seafloor sediment.

Partial List of Terranes of Washington State and British Columbia:

Wrangellia

Alexander Terrane

Turtleback Terrane

Deadman Bay Terrane

Garrison Terrane

Decatur Terrane

Haro Terrane

Methow Terrane (North and South subterranes)

Chilliwack Terrane

Vedder Terrane

Easton Terrane

Hozameen Terrane

Quesnellia Terrane

Cache Creek Terrane

Olympic Terrane

Okanogan Subcontinent

North Cascade Micro-continent

Insular Superterrane

Intermontane Superterrane

Intrinsic or inert

fire: basalt columns cut and polished, cast iron streetlight poles

and lamps. Elements are not site-fired (prefired during their original

formation), may be distributed differently than shown.

Cast iron “meteor” with

fossil surface in seafloor sediment impact crater. Interior of crater

and meteor fired, kiln removed at the peak of the firing revealing

red-hot meteor and sediment.

Two rocks from

different geologic terranes with Mt. St. Helens volcanic ash. Space

between the rocks is fired altering the rocks and fusing the volcanic

ash.

|

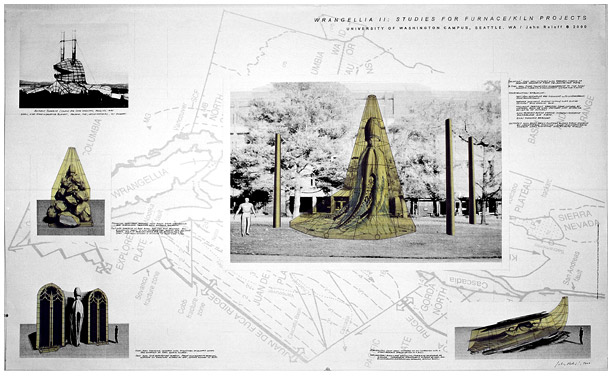

SELECTED

TEXT PANELS: WRANGELLIA II - left to right.

Standing cast iron

octopus with rocks from Wrangellia and Alexander Terranes and seafloor

sediment. Outside facing surfaces of base rocks are cut and polished..

All elements

fired to high temperature except for polished areas, rocks are altered

by heat, cast iron is allowed to rust over time.

Cast iron standing octopus with structure developed from windows

of UW’s

Gothic church. Cast Iron, cast refractory cement. Octopus is allowed

to rust over time, interior of structure altered by heat.

Horizontal cast iron octopus as an intrusion into a stratigraphic

sequence (sill).

Sedimentary rocks (ophiolitic/turbidite sandstone) or similar rocks.

Octopus is allowed to rust over time, interior of structure altered

by heat.

Drifting (cast

iron) octopus with coating of seafloor sediment from the Juan de

Fuca Plate. 3

cast iron flues connected underground to kiln/furnace

forming a downdraft system for firing.

Construction sequence:

Cast iron elements are installed with underground flue connections.

Seafloor sediment thickly placed over entire octopus.

Sediment partially eroded from octopus by natural rain or high pressure hose

revealing 40 - 60%of octopus.

Kiln/furnace placed around octopus/sediment assemblage and fired.

Kiln/furnace removed.Octopus will rust which further alters fired sediment by

leaching and staining; flues and underground system left standing, allowed to

rust. |